1.Machine Purpose:

Brand new configuration, dedicated for high diffculty digital printing design:

Guarantee the continuous motion of dossal lever chain won’t generate cloth ring swing, thus avoiding marking oflor dyeing defect appearing even in high difficulty digital printing.

Individual drive of dossal roller’s autorotation maintains the fabric on the dossal lever always under stable state.

thus greatly reducing color score or dyeing defect resulting from fabric corrugation or crimping.

Large spacing design of dossal roller allows the printing surface distance of fabric ring to be larger. When fabricmoves up and down, it won’t interfere mutually, More means avoids marking olf or dyeing defect even in high diffieultdigital printing.

Humidifying apparatus with patented design absorbs water from water tank making use ofsiphon prineiple, guaran-teeing 100% atomization and no spray-head block.

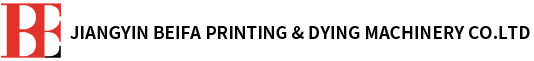

2. Professional technical guarantee creates the steamer brand of Beifa Company:

1. Steam box front cloth feeding is middle part initiative cloth feeding, reducing fabric tension and reducing ortrying to avoid fabric crimping.

2. From cloth feeding to ring and then to cropping: any position doesn’t contact the fabric front face, avoidingstaining.

3. Especially the dossal roller space is enlarged from traditional 152.4mm to 250mm, which guarantees the fabricwon’t contact and generate friction and avoids staining phenomenon.

4. The dossal roller self-rotation system is driven by independent motor. The rotating speed can be adjusted arbi-trarily according to production process, guaranteeing the fabric won’t crimp, wrinkle or stain.

5. This dedicated steamer has big steam box volume and small fabric holding capacity, thus guaranteeing thestability of temperature and humidity in the steam box, enabling the fabric color development to be more sufficient andstable!

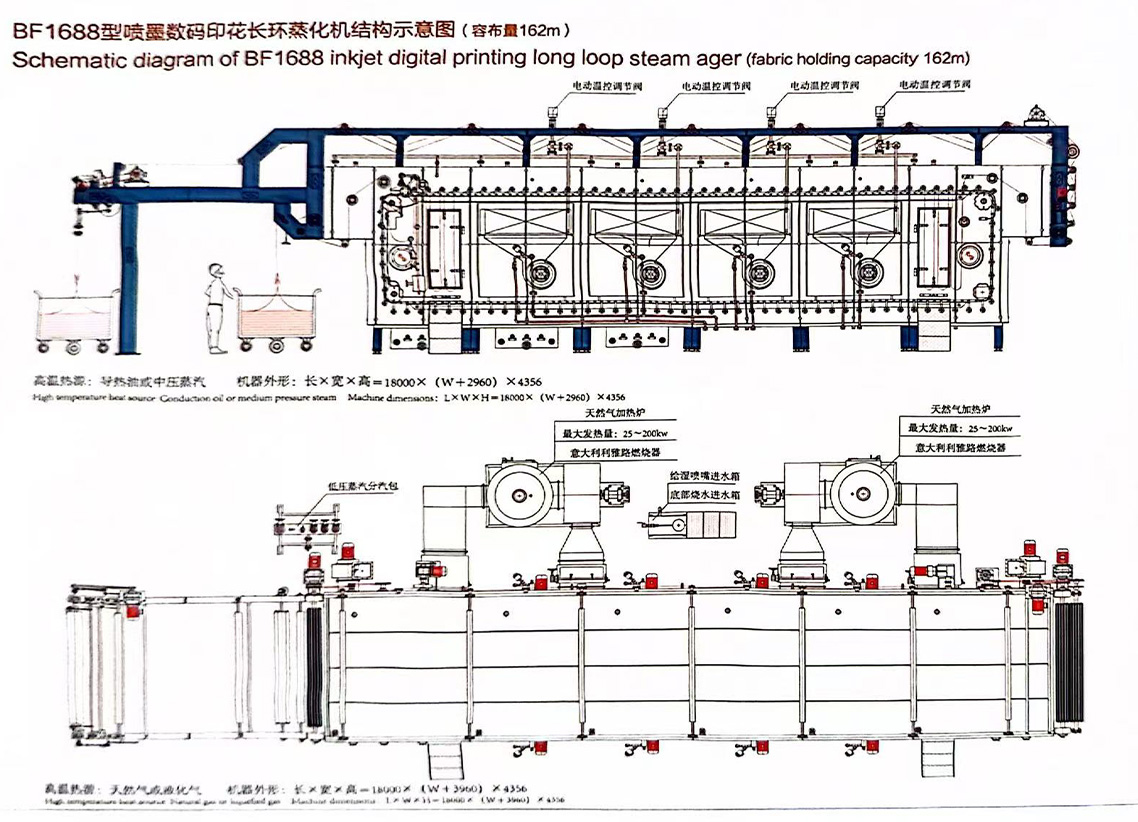

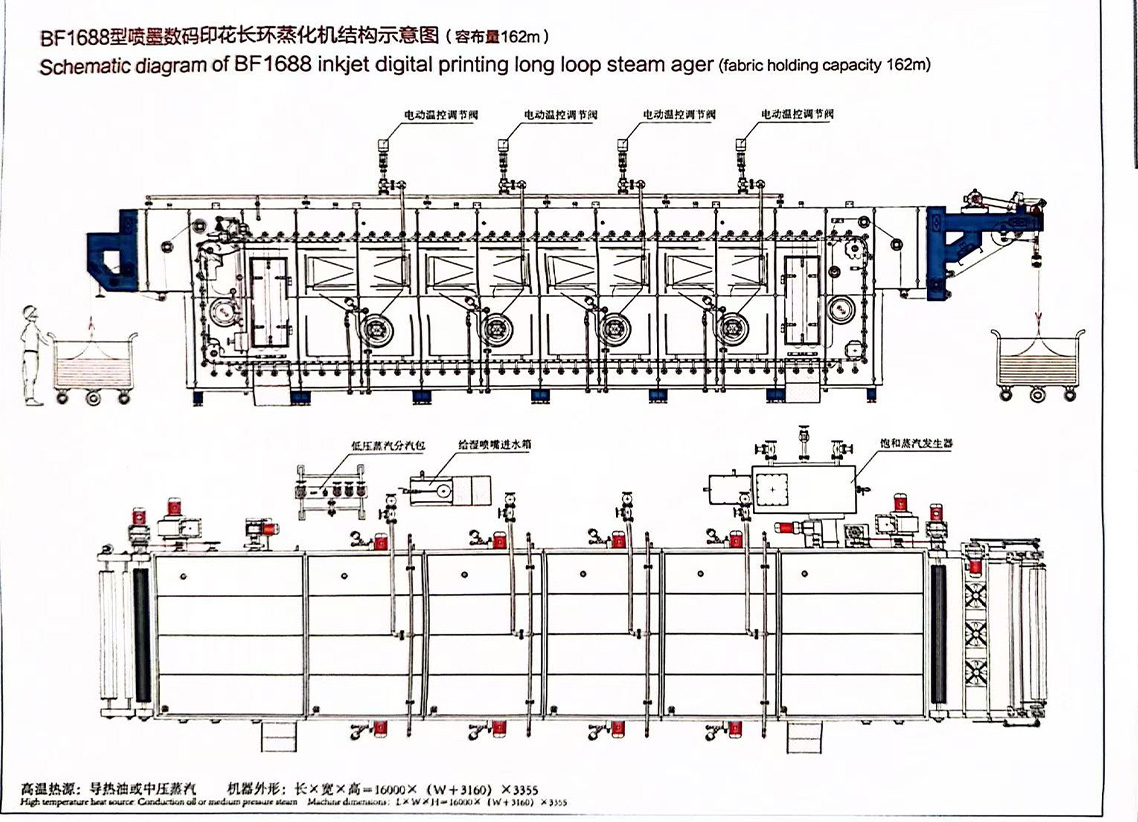

3. Main specifications and parameters:

1、1800mm-4000mm;1.Fabric width:1800mm-4000mm;

2, Fabric feeding and draw-out modes: Front feeding and font drawing oul, tont feecing and rear drawing out, single layer andsingle width; double layer and single width, double layer and double width;

3. Fabric holding capacity:70m,102m,134m,162m, 194m;

4.Loop length setting:lm~2m, stepless adjustable ;

5.Machine speed: 3m/min~35m/min;

6. Applicable products: Woven printed fabric, knilted printed fabric ;

7.Minimum pressure of steam supplied: 0.3mpa;

8.Applicable process: Active process ageing:102℃~105℃;Acid process ageing:102℃~105℃;Dispersingprocess ageing:175℃~185℃;

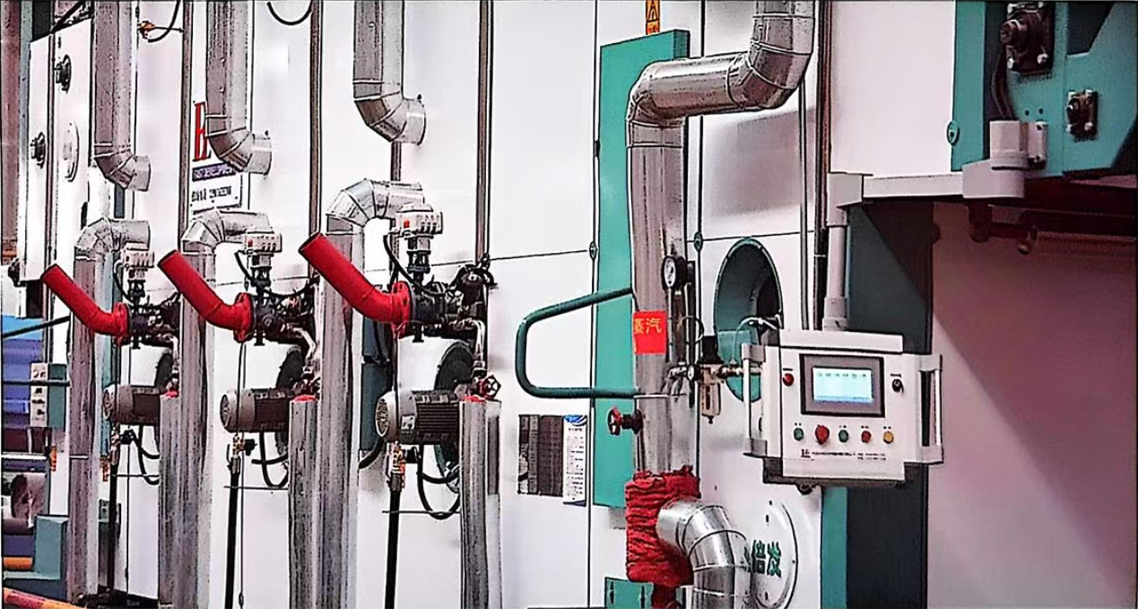

9. Conlrol precision of process temperature in the steam box≤+1℃

10.Overall steam consumption: 300kg/h ~ 450 kg/h;

11.Overall water consumption: 50kg/h ~ 80 kg/h;

12.Overall electrical control system adopts: PLC combinedwith man-machine interface touch screen technology, equippedwith fault diagnosis function, it operales in the form of no pause offabric hanging roller chain.

13. The position of looping pusher dog drive shaft is moved toabove the cloth hanging roller, the structure of pusher dogconnecting to shaft for conventional steam ager is cancelled, thuscompletely putting an end to the phenomenon of staining caused bycontact of front of printed fabrics with the drive shaft

14.verall driving motor: Variable frequency motor

15. Fabrie hanging roller automatic drive system adopts built-in motor drive, the rotational speed is adjustable arbimrarily according to the requirements of production technology, thus ensuring no edge curl, wrinkling or staining of fabric

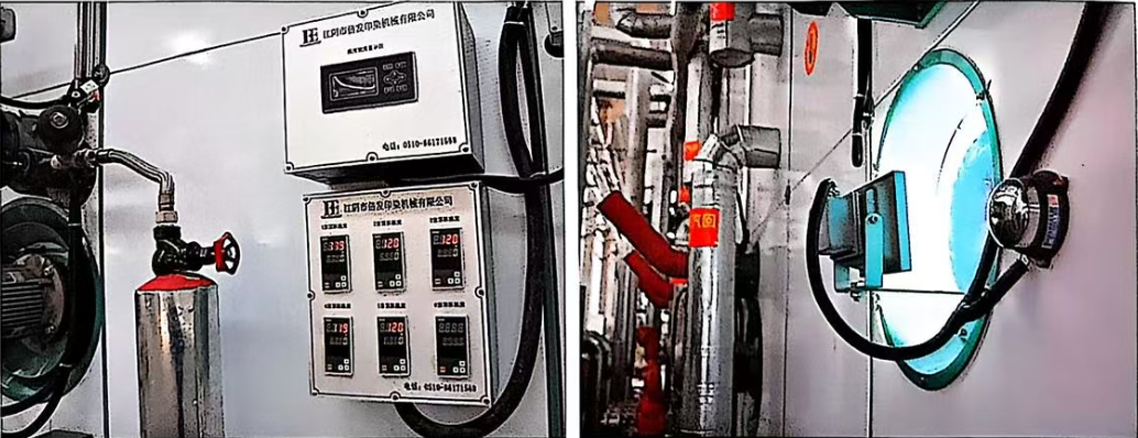

4. Special slructure of Beifa machine:

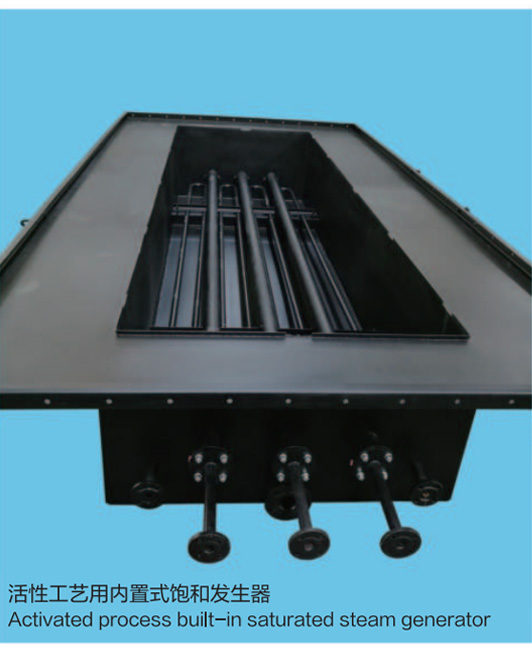

The fore-end chromophoric area of steamer is equipped with strong and sulicient new saturaled sleamhumidily and the supply size can be oplionally repulated. 0xygen supply device adjusled by proportion can make color brighler andncher.Newwel sprinkler without blockage perfectlyworking temperalure and humidity inside sleamer box.Witgood quality materials, especially development and applicalion of aeronautical aluminum alloy makes equipuient With good qualilymalerials, especially developmienl and applicalion of aeronaulical aluminum alloy makes equipment more anti-corrosive and durablthe slandardized heal lrealmen of all running parls by quenching and deepening ensures slablo oporalion and service life of miachineI'he poweriul and experienced deyelopmenl lcam has brought forth the new around the change of process and fabrio. With sovcranalional invenlions and utlily patents, ! lays a leading position in lechnology. Intelligent, onorgy saving and high oficient to crealowisdom new lexlile has always been the value of Beifa on he producl, Producls and qualily of Beifa has never been surpassod, but onlbe copied.(Characlerislics and palenls of Bcifa Company)

喂布輥

5. Main advantages and features of the equipment:

A. Mechanical Part:

1. Cloth-hanging roller inside steam box is made of p 50mm multi-angle aluminum alloy roller, embedded with 4anti-slip silica gel strip, light in weight and durable; curing use, it will self-rotate along orbit and avoid such defect asfiling bar printing, Aecording to different processes and fabrics, select to match: such three-mode cloth-hanging rollersas embedded rubber strip type, four-wing type and fine-tooth lype.

2. New humidification device; Using the siphon principle to fully atomize water, there is no nozzle blockage and the amount of water used is greatly reduced; And it can be disassembled without stopping the equipment, and easily and quickly restored, without affecting production and ensuring product quality through process assurance.